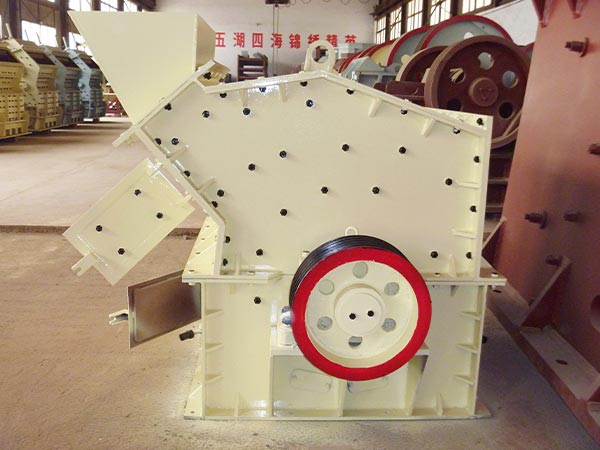

High-efficiency Fine Crusher is medium and fine material crusher combining domestic and international stone and sand industry specific situation, and it absorbs latest technology. It adopts advanced production technique and unique structure design. Fine crusher combines the advantages of hammer crusher and impact crusher, it leads in medium soft material crusher field. High-efficiency Fine Crusher has stable working performance and simple technique and structure, high capacity and longer service life.

crusher has learned the advanced mechanical technology at home and abroad and combines the domestic situations in the industries of cement, mining, ore beneficiation and building materials. It is used as a fine crusher to process materials with medium hardness and has better consumption reduction than the traditional roller press and has better comprehensive effect than cone crushers. All these features make the fine crusher able to effectively control the secular stability of the discharging granularity. The high efficient fine crusher also has the advantages of high crushing efficiency, low consumption, dust prevention, long lifetime of the quick-wear parts, low cost of the fittings, high running rate and simple maintenance.

It is a high efficient and energy saving crusher, which can save 50% energy by compared with the traditional fine crusher, so the high efficient fine crusher is the most advanced fine crushing equipment in the world.

It is used as a fine crusher to process materials with medium hardness and has better consumption reduction than the traditional roller press and has better comprehensive effect than cone crushers.

Advantages and features of the high efficient fine crusher: materials entering the cavity successively fall on the high speed spinning hammer and get crushed for the first time at the hammering zone under the action between the hammer and counter board. After high-frequency hammering and striking, materials fall on the median septum piling up and then they slide down on the bottom dumping disk of the high speed spinning rotor. Then materials are thrown to the impact plate at high speed and then are enforced to be impact, crushed and ground when passing the mobile board hammer. Therefore, materials are repeatedly crushed, washed and ground under the gravity action, thus realizing the fine crushing process.

| Model | Feeding Size(mm) | Capacity(t/h) |

| PXJ800×400 | <120 | 20-45 |

| PXJ 800×600 | <180 | 35-55 |

| PXJ 800×800 | <180 | 35-65 |

| PXJ 1010×1010 | <180 | 45-75 |

| PXJ 1200×1000 | <180 | 70-110 |

| PXJ 1200×1200 | <180 | 90-120 |

| PXJ 1400×1400 | <190 | 100-150 |

| PXJ 1600×1600 | <190 | 170-250 |

| PXJ 1800×1800 | <190 | 250-310 |